Description

Working principle

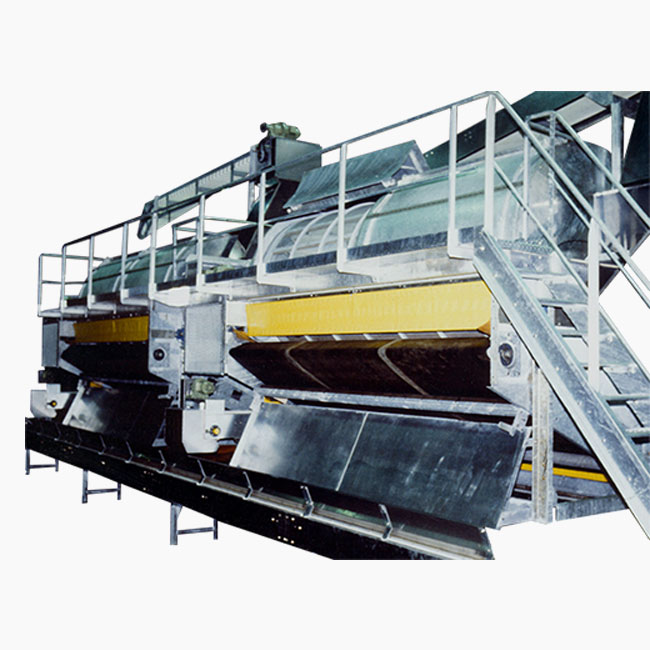

Un-opened pods are regularly fed through a feeding throat into a podding chamber. This chamber is made by the annular interval between :

• a solid internal drum equipped with whole length helicoidal plastic blades

• an external circular riddle drum equipped with screens and whole length wood beams.

The riddle drum turns at a set-up speed of about 6.5 R.P.M. and is driven by 4 trunnions assembled on to 2 lateral shafts running at the same speed. The shafts are themselves driven and linked by chains.

Thanks to the riddle drum beams, the pods are lifted on top and fall down on the blades of the internal drum, the speed of which is sufficient to progressively open the pods.

Each blow of the blades, due to their inclined positions, makes the pods move forwards inside the chamber.

Peas being freed from the pods are going through the external drum screens.

This drum has 7 zones of woven screens.

On standard version – zones are set as follow – from feeding end :

• 5 zones equipped with screens having 12 mm. square openings

• 2 zones with 14 mm. square openings.

The screens are assembled with bolts and can easily be replaced by other screens with different sizes of openings, according to peas varieties.

According to maturity and variety, the blow of the blade will have to be more or less important.

This is obtained by adjusting the speed of the inner drum.

Machine is delivered with 3 different sets of drive pulleys :

- 1 giving a rotating speed of 106 R.P.M.

- 1 giving a rotating speed of 95 R.P.M.

- 1 giving a rotating speed of 85 R.P.M.

End part of “podder” drum has no blades and its diametre is smaller. The chamber space is thus bigger in this area and makes it easier for the peas to escape from the open pods.

So, the open pods keep moving towards the open of the drum, while the peas together with small waste (broken pods + small unripen pods) fall down through the screens on a high inclined driven apron.

The top side of the apron sorts out product by 3 ways :

Shape :

• Flat waste (open pods – pieces of pods) do not roll and are carried upwards and discharged over top.

• Peas, of round shape, roll on the belt and go down the slope regardless of the upward motion of the conveyor.

Weight :

Peas which are heavier roll down, whereas waste which is lighter climbs up with the belt.

Sticking :

Wet waste tends to stick and is conveyed by the belt. The belt is cleaned on the return side by a rubber scraper.